|

|

|

Cell

A battery is an electric device

that converts chemical energy into electrical energy, consisting of a group

of electric cells that are connected to act as a source of direct current.

Batteries are made of connected cells encased in a container and fitted

with terminals to provide a source of direct electric current at a given

voltage. A battery is characterised by its chemical composition

(combination of metal(s) and electrolyte used), voltage, size, terminal

arrangements, capacity and rate of capability or more cells. In many

contexts it is common to call a single cell used on its own a “battery”.

In order for a cell or battery to be able to deliver

electrical current to an external circuit, a “potential difference” must

exist between the positive and negative electrodes. The potential

difference (usually measured in volts) is commonly referred to as the

voltage of the cell or battery. A single lead-acid cell can develop a

maximum potential difference of about 2 V under load. A completely

discharged lead-acid cell has a potential difference of about 1.75 V,

depending on the rate of discharge.

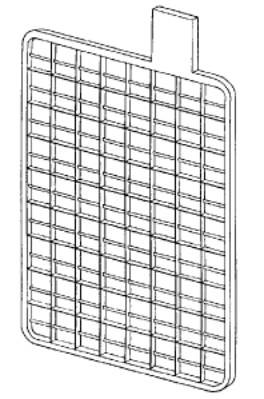

The simplest method for the construction of lead-acid

battery electrodes is the flat plate. It is merely a flat plate composed of

pure lead. Since the capacity of a lead-acid battery is proportional to the

surface area of the electrodes that is exposed to the electrolyte, various

schemes are employed to increase the surface area of the electrodes per

unit volume or weight. Flat plates are grooved or perforated to increase

their surface area. A typical flat plate is shown below:

Plate

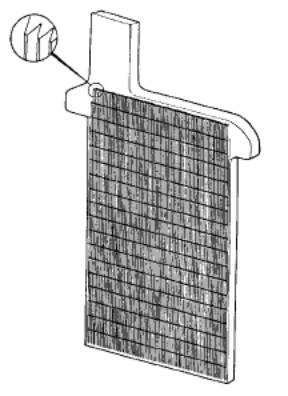

The most commonly used method to increase surface area is to make

the active material into a paste that acts like a sponge where the

electrolyte fills all the pores. The paste, or active material, is mounted

into a frame or grid structure that mechanically supports it and serves as

the electrical conductor carrying the current during both the charge and

discharge cycle. The most commonly used plate today is the pasted plate,

also known as the flat plate. This grid structure is a latticework that resembles

the cross section of a honeycomb, with the paste filling all of the

rectangular windows on the structure. The picture below shows a typical

construction of a pasted plate grid. The flat plate construction is used as

the negative electrode plate in almost all cases, and serves as the

positive plate in most standby applications.

Pasted Grid plate

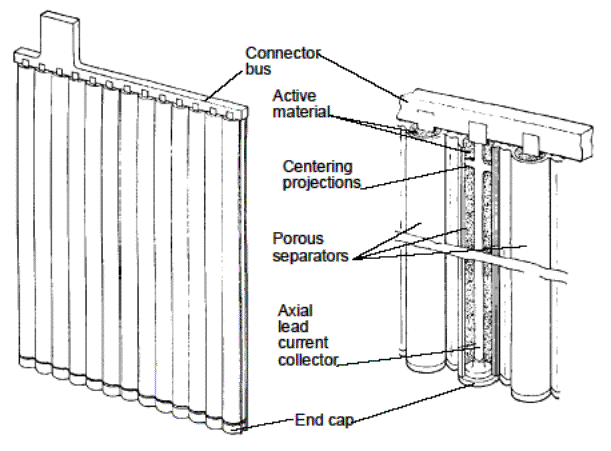

Positive electrodes are usually of pasted plate or tubular

construction. Tubular electrodes are popular positive plates for heavy cycling

applications. This construction uses a frame structure consisting of a

series of vertical spines connected to a common bus. The paste is held in

micro-porous, non-conductive tubes, which are placed over the individual

spines. A simplified view of tubular plate construction is shown in below.

Regardless of the plate type used, the capacity of any battery is increased

by adding multiple plates in parallel.

Tubular Plate

Back to top Back to top

|

Have questions? Contact TECH SUPPORT:

Corporate

|

About Us | Site Map | Services | Clients | Global Presence

| Email: Parts &

Service | Battery Care

Privacy |

Terms of Use |

Ethics |

Legal

Powered by: Sun Microsystems

© Copyright GB Industrial Battery - All rights reserved.

Last Updated: Monday, December 03, 2007 - 6:00 AM Eastern Time.

|